MULTIline F

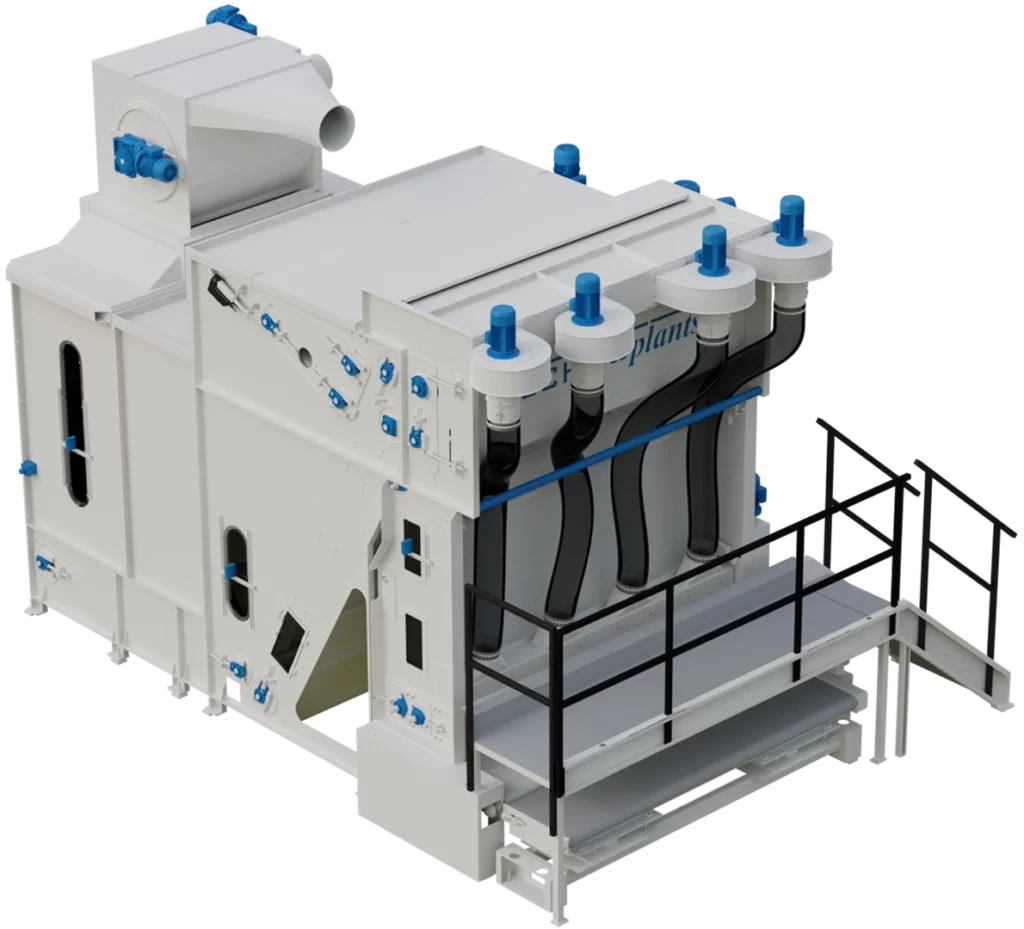

The airlay unit mod. f is a purely aerodynamic forming system. It is the preliminary batt forming and feeding system for the following airlay carding units p or s, c or d. Thanks to the weighing system in exit, PID control and possibility to adjust the formation chamber, the airlay f can also be used […]

MULTILine L

The web forming unit mod. L is a volumetric feeder with special characteristics. The web forming chute in exit is complete with variation of the chamber gap and vibrating wall. In this way the feeder L works as a standard volumetric feeder. The exit chute is also equipped with a series of blowing motorfans which […]

Airlay line for needlepunched products

MULTIline C

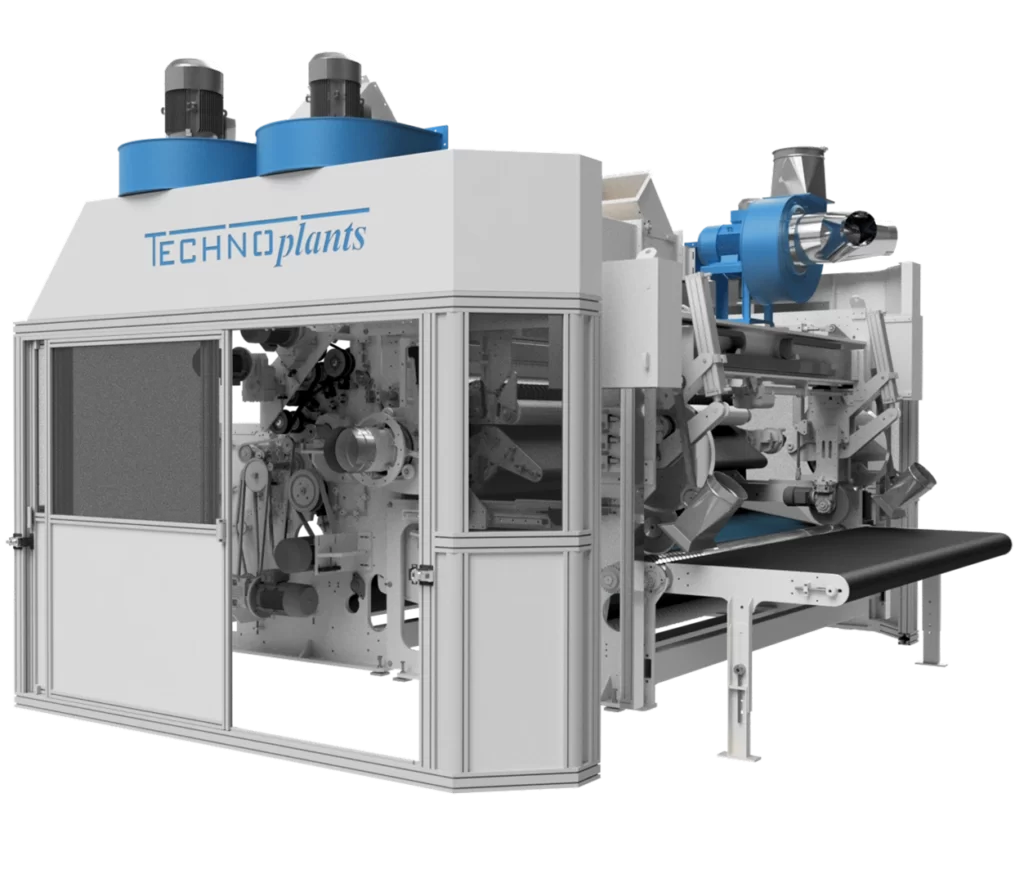

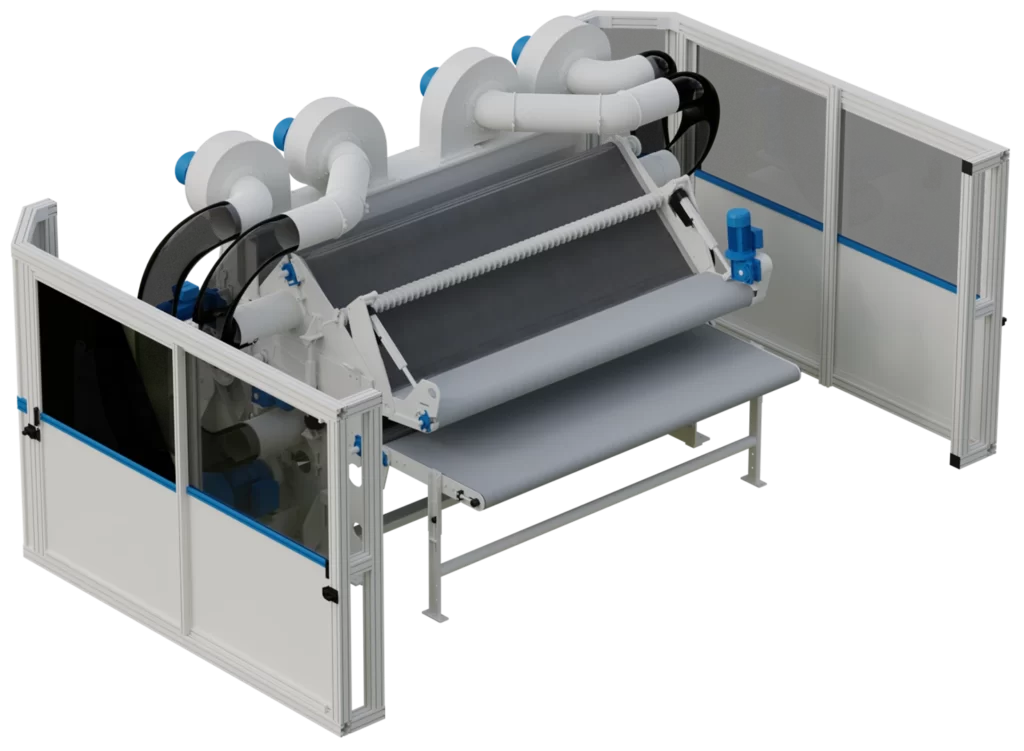

The Airlay unit mod. c works with a combination of several carding cylinders clothed with rigid wires, followed by a top + bottom air shaping system. The airlay card model C allows the maximum fiber opening degree among the MULTIline range of machines, making it particularly suitable for nonwovens with light and medium gsm, starting […]

Lamination line/ Converting

MULTIline D

The airlay card mod. D works on the same principle of the airlay card mod C. In addition to the standard top + bottom air suctions in exit, the airlay card in this version is equipped with a doffing system similar to the one of traditional roller cards. The doffing system allows to produce light […]

Phenolic resin line

MULTIline P

The airlay card model P performs a homogeneous opening and blending of the fibers thanks to its first section composed of carding cylinders; at the same time it allows to obtain nonwovens of medium and high basis weights, thanks to a particularly powerful and wide-adjustable suction system in exit. The combination of these two characteristics […]

Vertical Lapper line

MULTIline S

Special design that allows the aerodynamic web formation of fiber mixes or fiber + powder mixes, all in one machine. Unlike with traditional airlay technologies, using the airlay card mod. S there isn’t the need to set up two separate lines – one dedicated to resin curing and one to bonding with low melt fibers […]