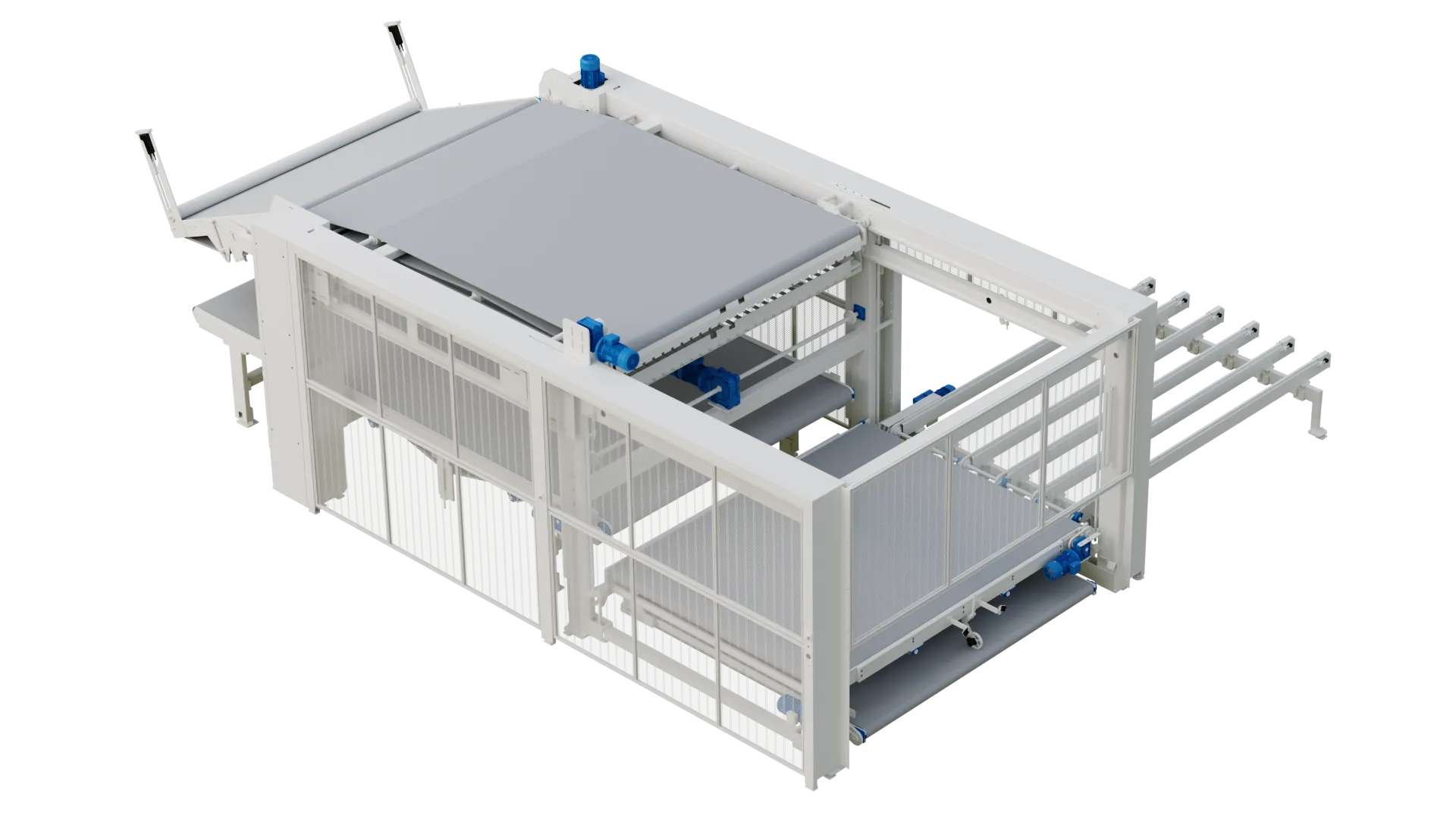

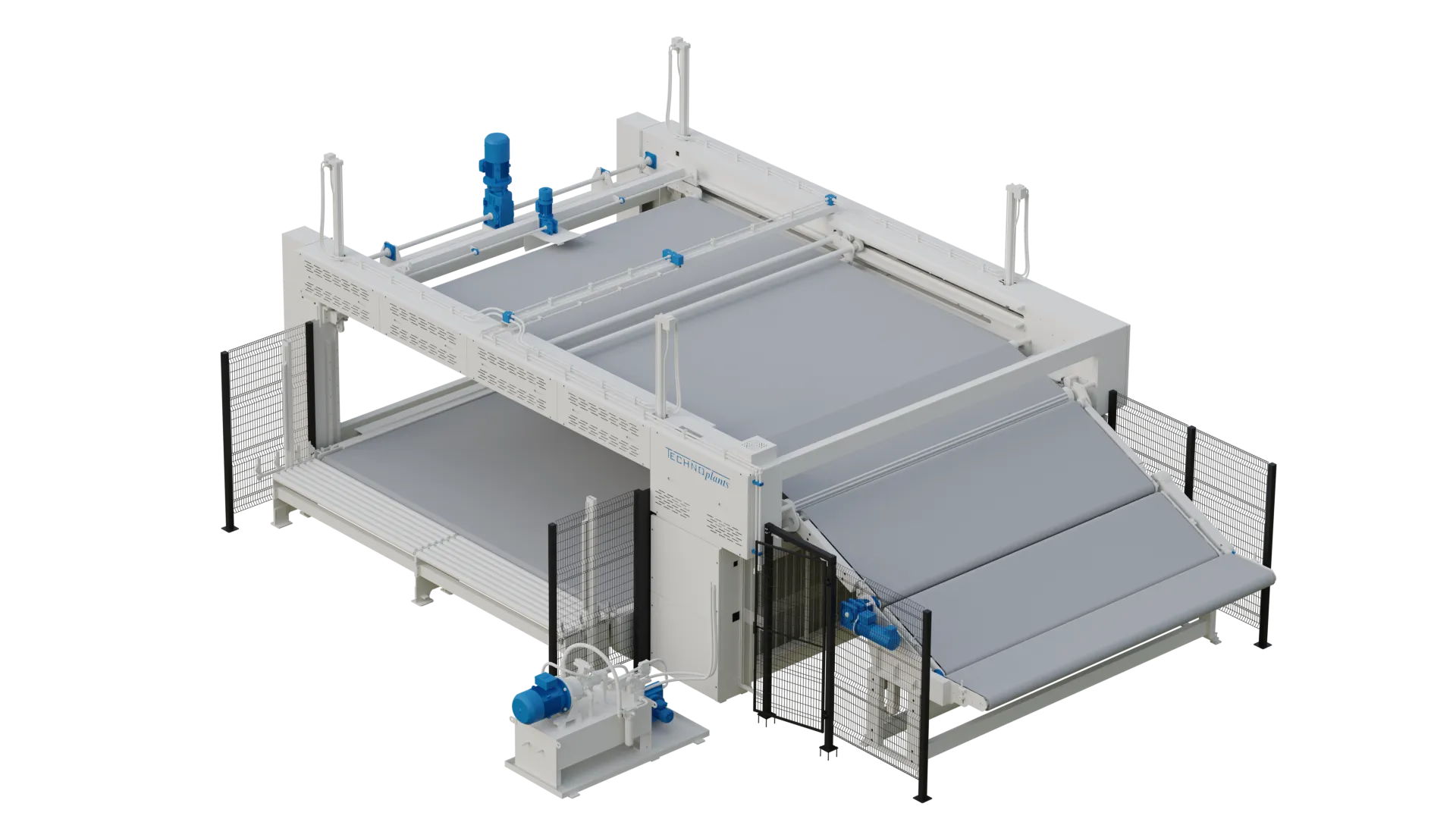

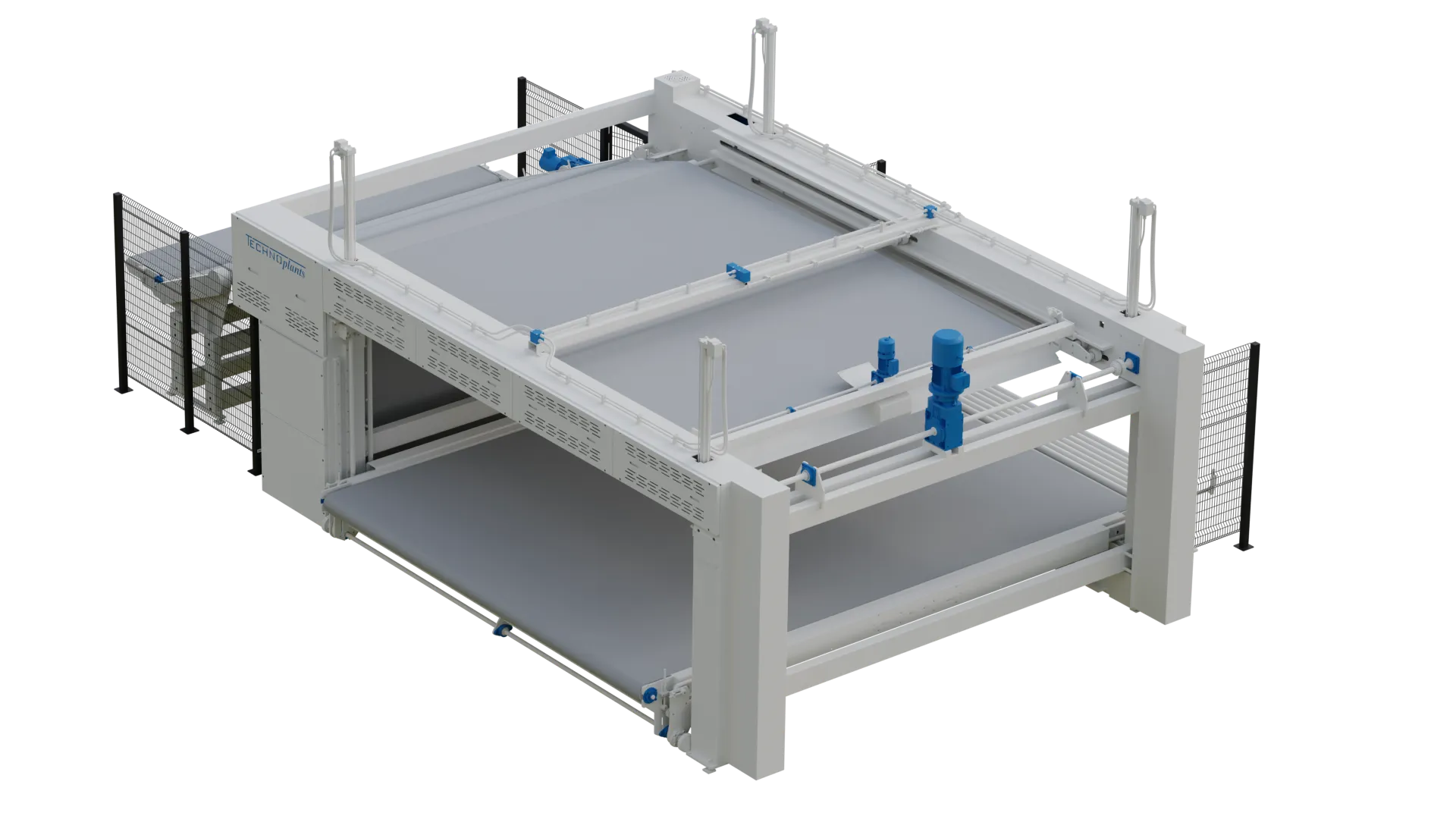

The Technoplants stacker has been designed to take the felt panels coming from the cutting unit and arrange them one above the other on a stack.

High stacking precision and double stacking position to meet the strictest tolerances and the highest speeds.

Continuous stacking cycles even during unloading of the full stack of panels.

Number of pieces settable from the control panel.

Stacking centered or lateral to the support pallet.

Fork stacker for wadding: Unloading with chain conveyor, to allow easy picking up with the forklift.

Belt stacker for needled products: Designed for handling high stacks of soft panels.

Also available in double position.

Unstacker: Technoplants is also able to supply unstackers machine to feed the stacked panels one by one to downstream processes such as molding presses or press ovens.