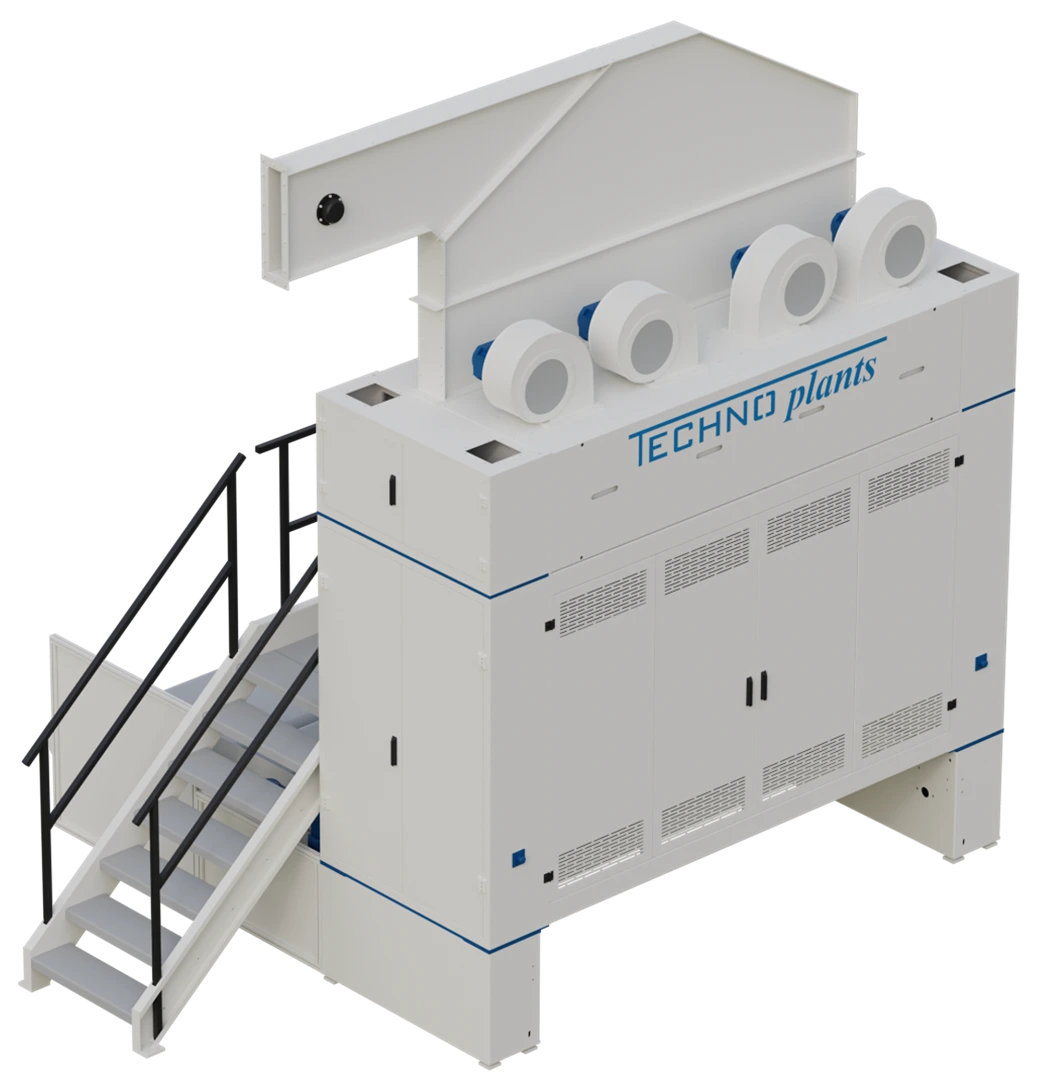

L’unità airlay mod. f è un sistema di formatura puramente aerodinamico.

È il sistema preliminare di formazione della falda e alimentazioni delle carde ad aria mod. p o s, c o d.

Grazie al sistema di pesatura in uscita, al controllo PID e alla possibilità di regolare la camera di formazione, l’Airlay f può essere utilizzato anche come sistema di formazione Airlay indipendente, bypassando le successive sezioni di cardatura airlay (quando presenti).

Non avendo elementi di apertura, l’unità Airlay F è adatta a formare non-tessuti da materie prime non fibrose, come pezzi di schiuma o palline di fibra.