Technoplants has developed an air forming unit based on pneumatic formation. The pressure feeding assures an high accuracy in cross section, and then an homogeneous fiber web formation.

It can be used as a card feeding system or for direct fiber web formation to feed ovens or other bonding systems.

The machine can be equipped with a belt weigher to better control weight in cross and longitudinal direction.

The machine can manage long, short, virgin and recycled fibers.

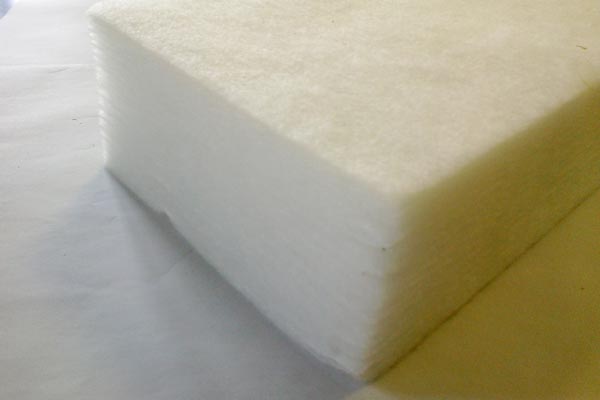

Insulating waddings

Glass fiber pads

Card feeding

The pneumatic forming unit gives top performances in web cross regularity. For this reason it is suitable to feed top performance card machines which require strict tolerances in terms of weight and productivity.

The belt weighing system is a further guarantee for longitudinal stability in term of weight.

Technoplants has developed a glass fiber line on the base of the pneumatic feeding unit.

The pneumatic feeding is able to vertically displace the fibers, allowing a better resilience and elasticity of the wadding.

The product is then able to return to the original size even after 6 months from the packaging operation.

The forming unit includes a fine opening group and a launching fan which can be included in a standard thermo bonding line.

The pneumatic forming unit can manage a huge variety of fibers for a range of differente application fields such as insulating products thermo- and sound- proofing, furniture, mattresses, automotive. The machine is composed by:

The unit can directly feed an oven, a needle loom or any other kind of bonding machine